Benefits of VFM Technology

Benefits of Rapid Heating

- Increased Throughput Potential

- Reduction in Work In Process Inventory (QC)

- Reduced Thermal Budget (Parts time @ Temp.)

- Fast Cure Minimizes Part Movement

Benefits of Selective Heating

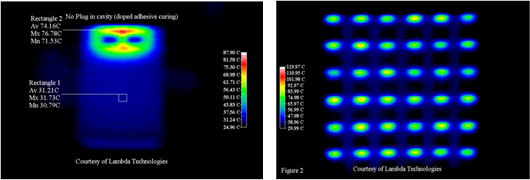

- Reduced Stress Build-up (CTE Mismatch)

- Enhances Selection of Materials / Design

- Reduced Thermal Budget on Adjacent Components

Benefits of Low Temperature

- Stay below temperature threshold of devices

- Low thermal stress and warpage

Benefits of Precise Cycle Control

- Cycle Optimization thru Stepped Profile

VFM Applications Markets

| Application |

Convection |

VFM |

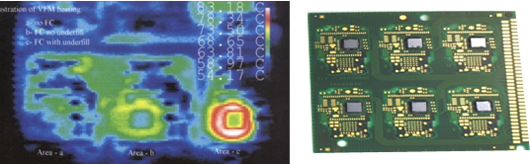

| Flip Chip |

30 mins ~ 2 hrs |

2 mins ~ 10 mins |

| Glob Top |

1 hr ~ 2 hrs |

5 mins ~ 10 mins |

| Post Mold Cure |

4 hrs ~ 6 hrs |

15 mins ~ 20 mins |

| Wafer Coating |

4 hrs ~ 8 hrs |

20 mins ~ 60 mins |

| Flex Coating |

4 hrs ~ 5 hrs |

10 mins ~ 20 mins |

| Smart Card |

6 hrs ~ 12 hrs |

2 mins ~ 5 mins |

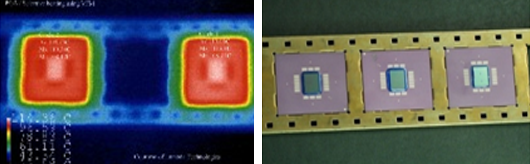

| Die Attach |

1 hr ~ 2 hrs |

5 mins ~ 10 mins |

| Optical |

1 hr ~ 2 hrs |

10 mins ~ 15 mins |

| Ceramics |

1 day ~ 7 days |

20 mins ~ 4 hrs |